phone

+8610 63173722

Lightweight

Minimalist Door

Product introduction:

Technical highlights:

Integrated flexible storage space

Integrated smart induction door locks

A new sealing structure that helps hidden inside and outside belt lines

Detachable outside door panels that can be customized

Extreme simplicity in appearance

Attractive appearance that enhances customer experience

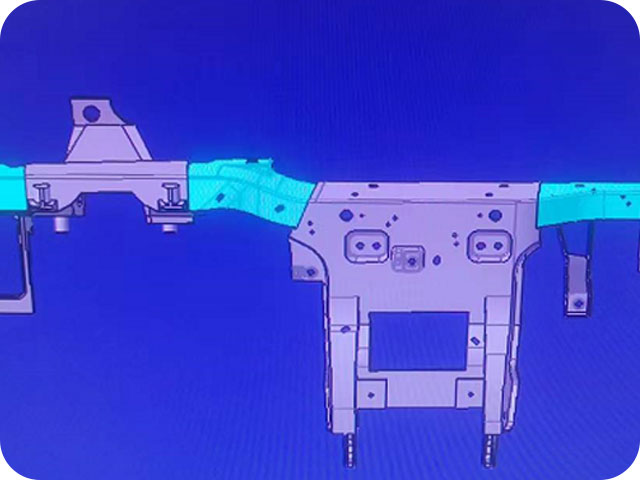

Multiple Materials Composite CCB(Cross Car Beam)

Product introduction:

Technical highlights:

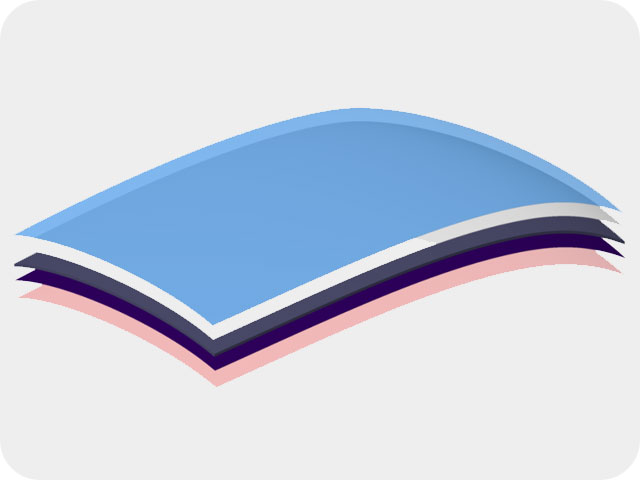

Intelligent Dimmable Skylight Glass

Product introduction:

Technical highlights:

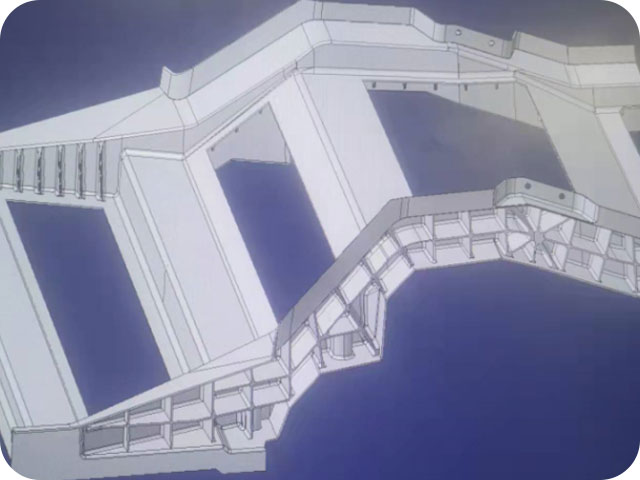

Large Aluminum Alloy Die Casting

Product introduction:

Technical highlights: